Let’s face it, low voltage LEDs and Power Supplies are high-tech, but in reality they are more simple than you think! Even wiring up a small sign is pretty basic. When you get into larger signs with more modules and larger power supplies, that's when things get complicated. Understanding the product specifications and UL requirements to build your sign up to code can get confusing. So, let us help!

At HanleyLED, we are all about “High Efficiency Everything”. Understanding the intricacies of wiring up your LEDs and Power Supplies will help your team create the most efficient wiring plan ahead of time.

Terminology

Below are some important terms and topics that every Installer, Estimator, Service Technician and Production Manager at a sign company should understand to gain what we call “2e Status” - Effective & Efficient.

Cascade Limit: (Daisy-chain Limit or Mods in a Series) Simply the number of modules that you can daisy-chain in a single string off the end of the power supply, without the voltage drop affecting the brightness of the LEDs at the end of your string/run. It does NOT refer to the quantity of modules that you can attach to a power supply, but simply how many modules you can run off the power supply before having to run the rest of your LEDs back to your power supply.

Two major factors impact the cascade limit:

- Constant Current (CC) v Constant Voltage (CV) LEDs: Constant Current modules help boost the current in your LED line as the voltage drops. This allows longer cascades off the end of the power supply compared to Constant Voltage LEDs.

- LED Voltage: Voltage impacts how many LEDs you can cascade in a daisy chain off the end of a power supply. 24V electricity is stronger and therefore can carry the current further, allowing longer cascades.

For example: Our PhoenixNRG Family has both a 12V and 24V version of the same module.

12v PhoenixNRG 2 (PE-2): You can run (96) modules on a 60W power supply. But the “Cascade Limit” is (40) modules. So you have to break your (96) modules into (3) runs and connect each run to the power supply.

24v PhoenixNRG 2 (PN-2): You can run the same amount of modules of PN-2 (96) on a 60W power supply as HanleyLED’s 12v PE-2, however the Cascade Limit is (80), meaning you can daisy chain more LEDs off the end of the power supply. So, where as the 12v PE-2 suggests that you break up your (96) modules into (3) runs, the 24v PN-2 only needs to be broken up into (2) runs.

The Cascade Limit for each brand of modules and each model number within a brand is different. You can find the specific Cascade Limit on your preferred LED brand’s spec sheets.

Class2: A safety rating required by UL for power supplies to be used in LED illuminated signage. In order to have a Class 2 rating, each output on a power supply cannot provide more than 5amps.

For example: a 60W 12v power supply has (1). A 100W 12v power supply has (2) outputs because 100W/12v = 8.33A (more than 5A). However, a 100W 24v power supply has (1) output because 100W/24v = 4.16A

Power Factor: Ratio of real power to the apparent power flowing in the circuit. Low power factors draw more current, therefore decreasing the amount of power supplies that you can run on a circuit. On the other hand, power supplies with HIGH power factors pull less amps, allowing you to put more power supplies on a circuit.

Input Current: Maximum power input for a single power supply. A lower number allows more power supplies per circuit.

IP Rating: The dust and waterproof rating for products. The first number listed refers to the dust rating (1-6, 6 being the highest) and the second number listed refers to the water rating (1-8, 8 being the highest).

UL iq Database

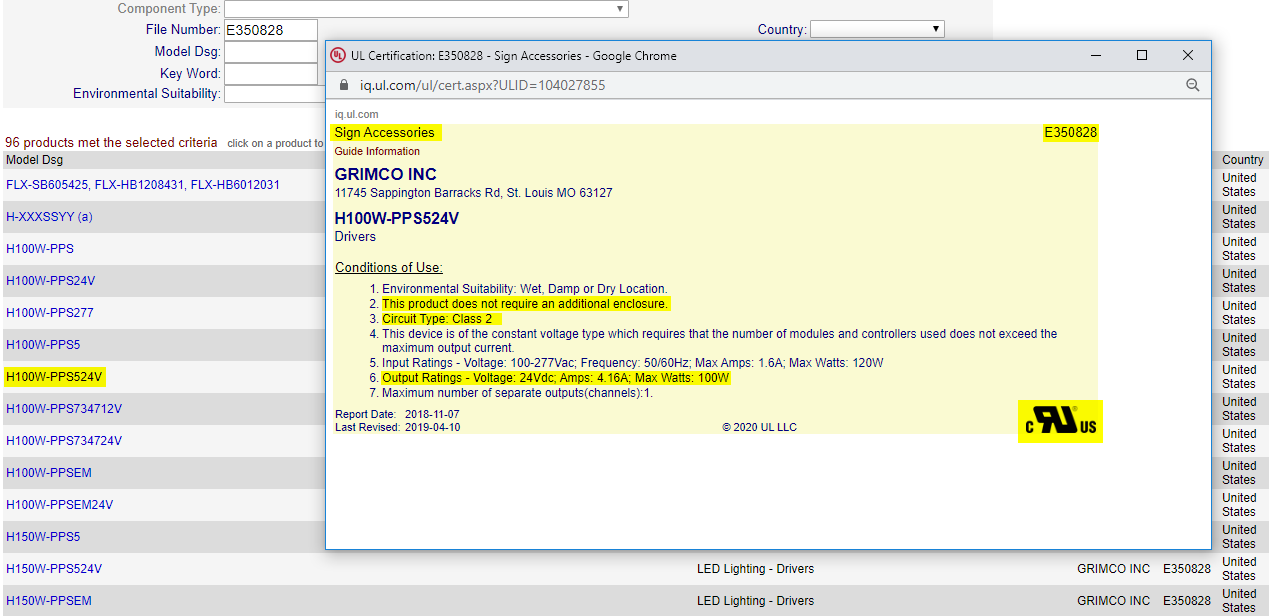

It is important to make sure that the products you are using in your signs are UL Recognized, to ensure that your sign passes your UL inspection. UL iq is UL’s online database for sign manufacturers to learn if their products are not just “UL Recognized”, but UL Recognized for use in LED signs. HanleyLED’s UL Number is E350828. If you search for that within the database, you’ll see the list of all of our UL Recognized products under that e-file number.

Additionally, this is where you can find out what the “Conditions of Use” are for your LED products. For example, if the Conditions of Use say that your power supply requires an electrical enclosure then you need to take additional consideration into the cost of your sign for the labor and materials needed to enclose your power supply. You can find our Conditions of Use on the database when a power supply is chosen.

Common Wiring Methods

- Single-Ended Power Feed: Running a single string of LED modules off the output of your power supply. One end is connected to your power supply, while the other is simply capped off with wire nuts.

- Parallel Wiring: This is like a “single-ended power feed”, but with multiple runs of LEDs attached to the same power supply. Multiple strings of LEDs are independently running back to the power supply.Note: This is used most often with larger power supplies - 100W, 150W or 250W - when the number of modules attached exceeds the Cascade Limit spec of your LED module.

- Home Run Loop: This is where you have two long runs of LED strings tied together on one end and both connected to the power supply at the other, forming one giant loop.

Note: This is also used when the number of modules attached exceeds the Cascade Limit. It reduces brightness differences between the first and last LED, while also reducing the number of times an installer might daisy-chain too many LEDs together.

The HanleyLED Difference

HanleyLED Power Supplies are created to last, with our customers, labor force and the end-user in mind. Our Quality Control is 2nd to none, awarding us with the lowest service and failure rate in the industry! Our wide range of options fit varying product and budget needs while continuing to provide the best quality possible. Every single power supply we produce runs through a pipeline of intense quality checks to ensure the final product earns your trust and meets your needs.

A total of 39 tests occur throughout our quality control system. From our rigid recipe of Tier 1 components and initial raw material testing, to our final 16 hours of "All Systems Go" tests at the end, quality is the life behind our line.

All HanleyLED power supplies have a higher power factor to combat the issue of energy loss in distribution. This means that you can run MORE power supplies on a single 20amp circuit, ultimately saving you on time and labor costs on your entire project. Each driver is also IP68 rated and is dry, damp AND wet rated by UL. Our top priority throughout product development is you! We work hard to supply leading solutions that give you confidence on the job.